Context & Vision

Mick’s team re-engineered outdoor fitness with rugged, inclusive machines for all users, including wheelchair athletes, combining cost efficiency with a bold visual identity. Research and immersion defined key strategy pillars — inclusivity, durability, efficiency, and striking aesthetics—while testing and simulations refined ergonomics, functionality, and a new unique competitive design language.

Challenge

The client needed outdoor equipment that would: meet high standards of durability under constant weather exposure, be truly accessible for wheelchair users without sacrificing usability for standing users, address factory and technical constraints (CNC tube bender, welding equipment, weight limits, materials), stand out visually with a strong, bold identity. In short—align performance, accessibility, manufacturability, and aesthetics.

Solution

Design Strategy

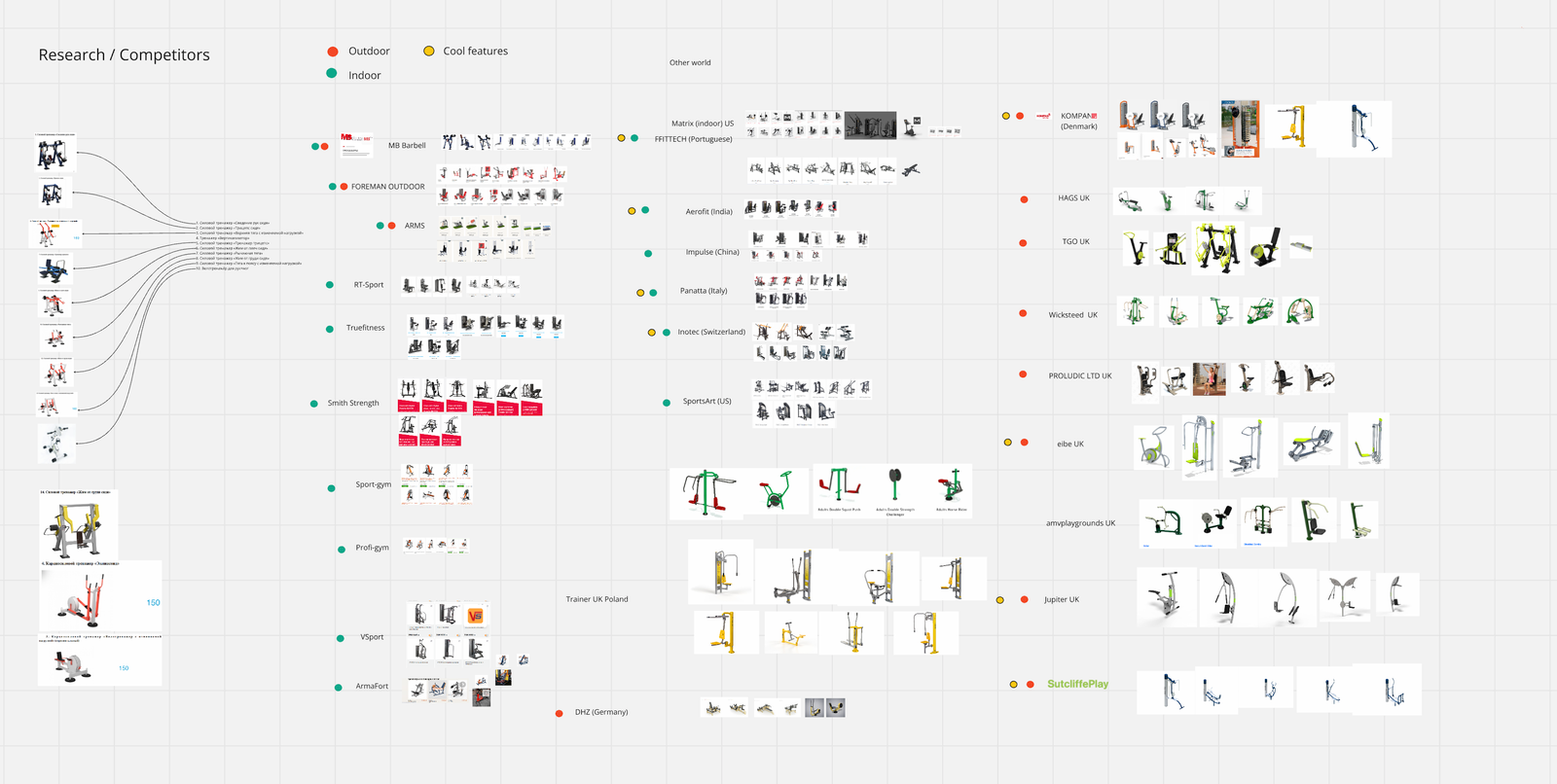

The process began with deep immersion inside the factory, observing machines, tools, and assembly workflows to map both opportunities and constraints. Market research and competitor analysis highlighted how few products truly addressed inclusivity, revealing a strategic gap to position accessibility as a core value. From this, guiding principles emerged: machines had to be inclusive, durable, efficient, and carry a bold visual identity that would stand out in public spaces. These insights shaped the strategic framework that guided the entire project

Industrial Design Implementation

With the strategy in place, concepts moved into design development. Sketches were translated into the Concept Design, CAD models and detailed technical drawings, setting clear parameters for engineering and manufacturing. Prototypes were produced and tested outdoors to validate ergonomics, durability, and accessibility under real conditions. Each iteration informed refinements, from structural details to user interactions. The production phase was guided closely, with attention to fabrication techniques, material behavior, and finishing quality to ensure the machines aligned with both the functional demands and the envisioned design language.

Outcome

The project delivered a bold and competitive design language that now guides future equipment development by the in-house team. By adding bending and reducing welding, production became faster and machines were made 30–40% lighter, lowering delivery costs and simplifying installation. Ergonomics were improved through real-world testing and advanced computational analysis, raising comfort and safety for all users, including wheelchair athletes. The machines significantly boosted sales, gained strong attention at fairs and exhibitions, and drew interest from hospitals, government institutions, and communities. Their striking identity also made them Instagram-worthy objects—embraced as much for social and cultural presence as for fitness.

From Challenge to Conclusion

Step by step, this process reveals how the project moved from identifying the challenge to delivering measurable impact.

1. Framing the Challenge

The client set a clear task: create a new line of inclusive fitness machines, accessible to all users, including those in wheelchairs. The goal was to balance accessibility, durability, and cost while building a strong product identity.

2. Immersion & Opportunity Mapping

The project began with a factory visit. Meeting management and workers, Mick assessed machine tools, welding setups, and assembly lines. This immersion revealed real production opportunities and constraints — shaping what could be designed and how it could be made.

3. Research & Design Strategy Development

Mick mapped the global and local fitness equipment market, studying ergonomics, durability, and inclusivity. This strategic scan highlighted gaps and positioned the project to compete through accessibility and bold design.

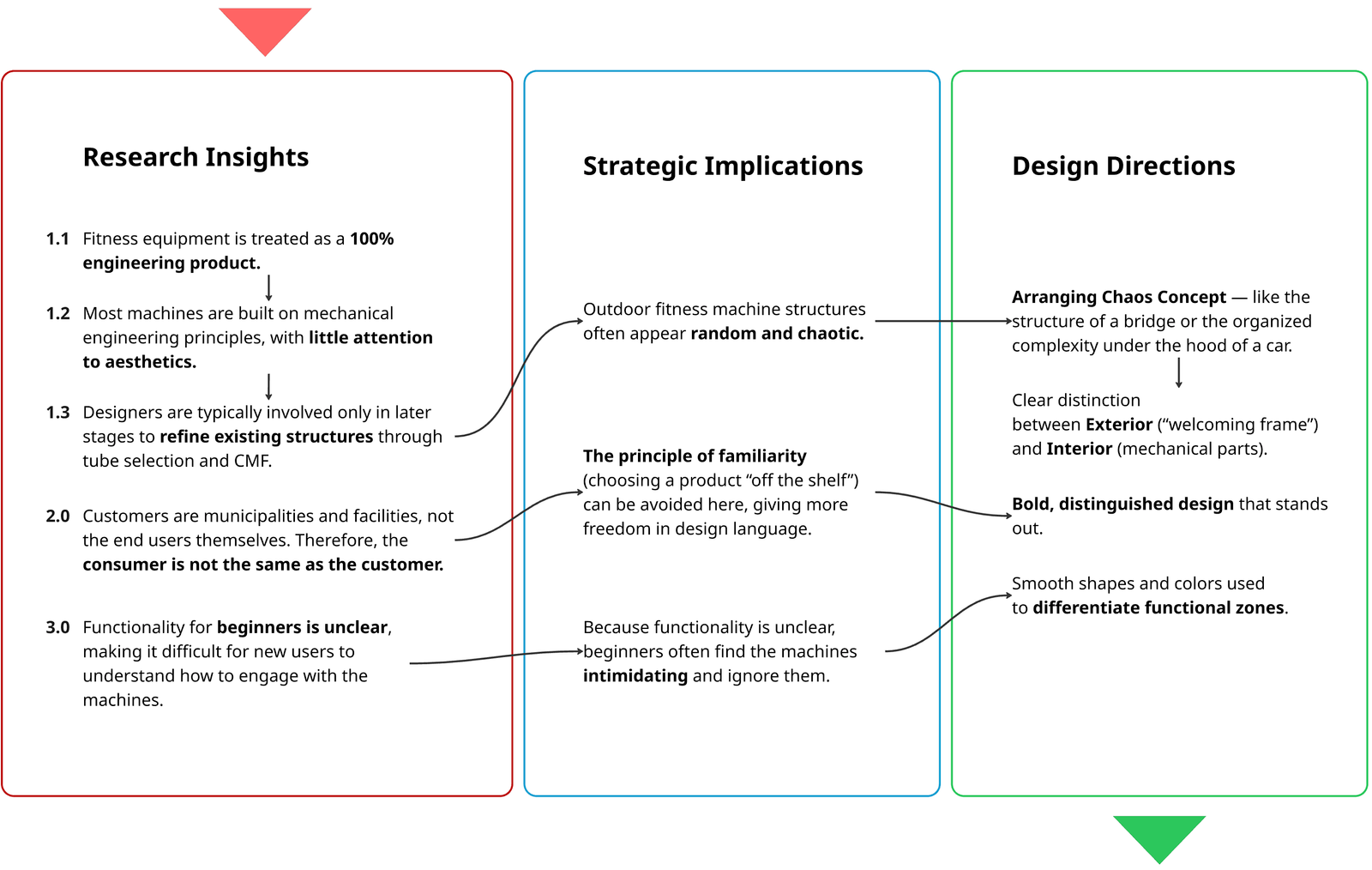

Turning Research Insights into Design Directions

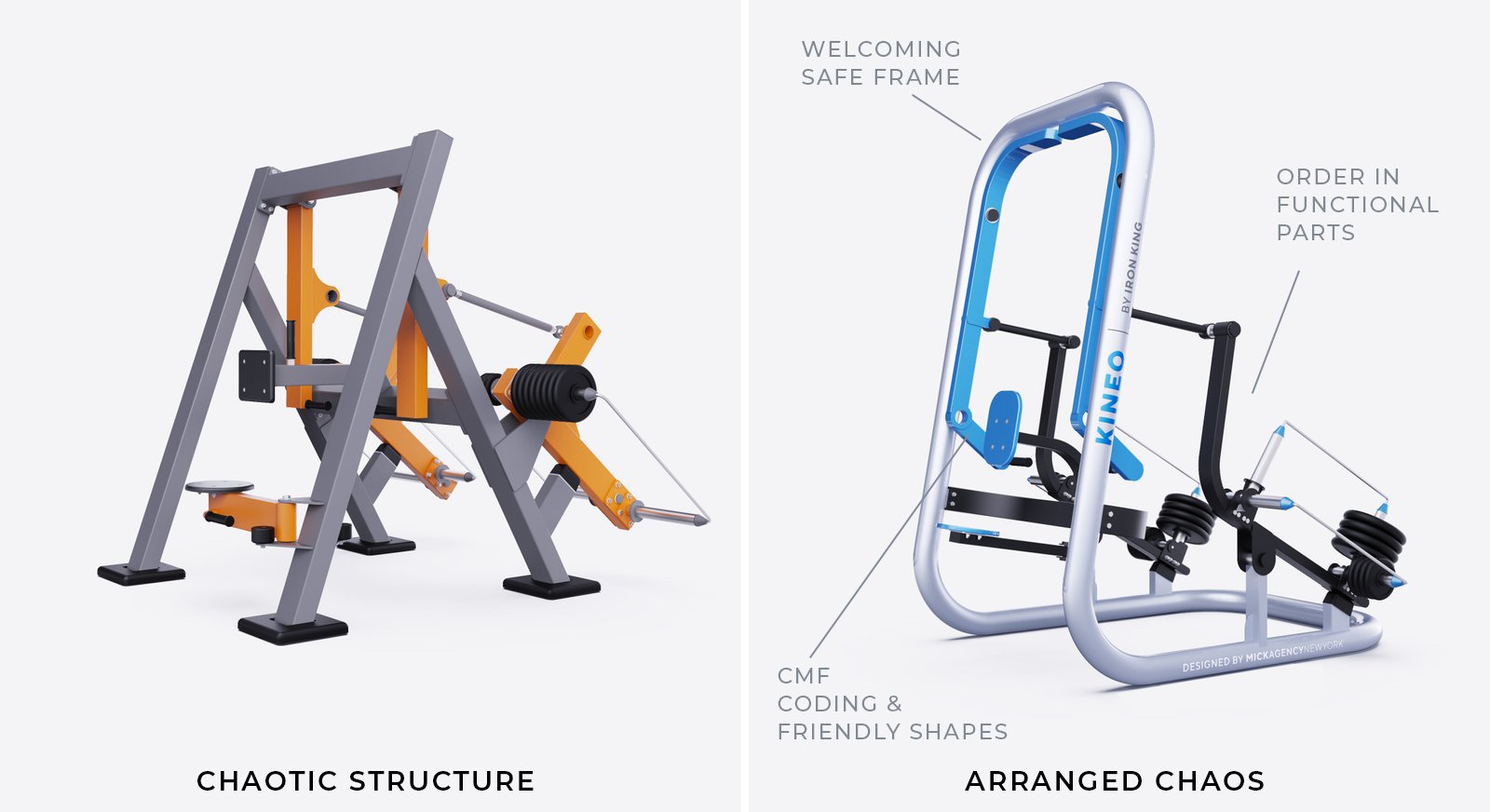

Arranging Chaos / Direction

Functionality can be beautiful. Bridges and car components show how pure engineering can be arranged with clarity and elegance.

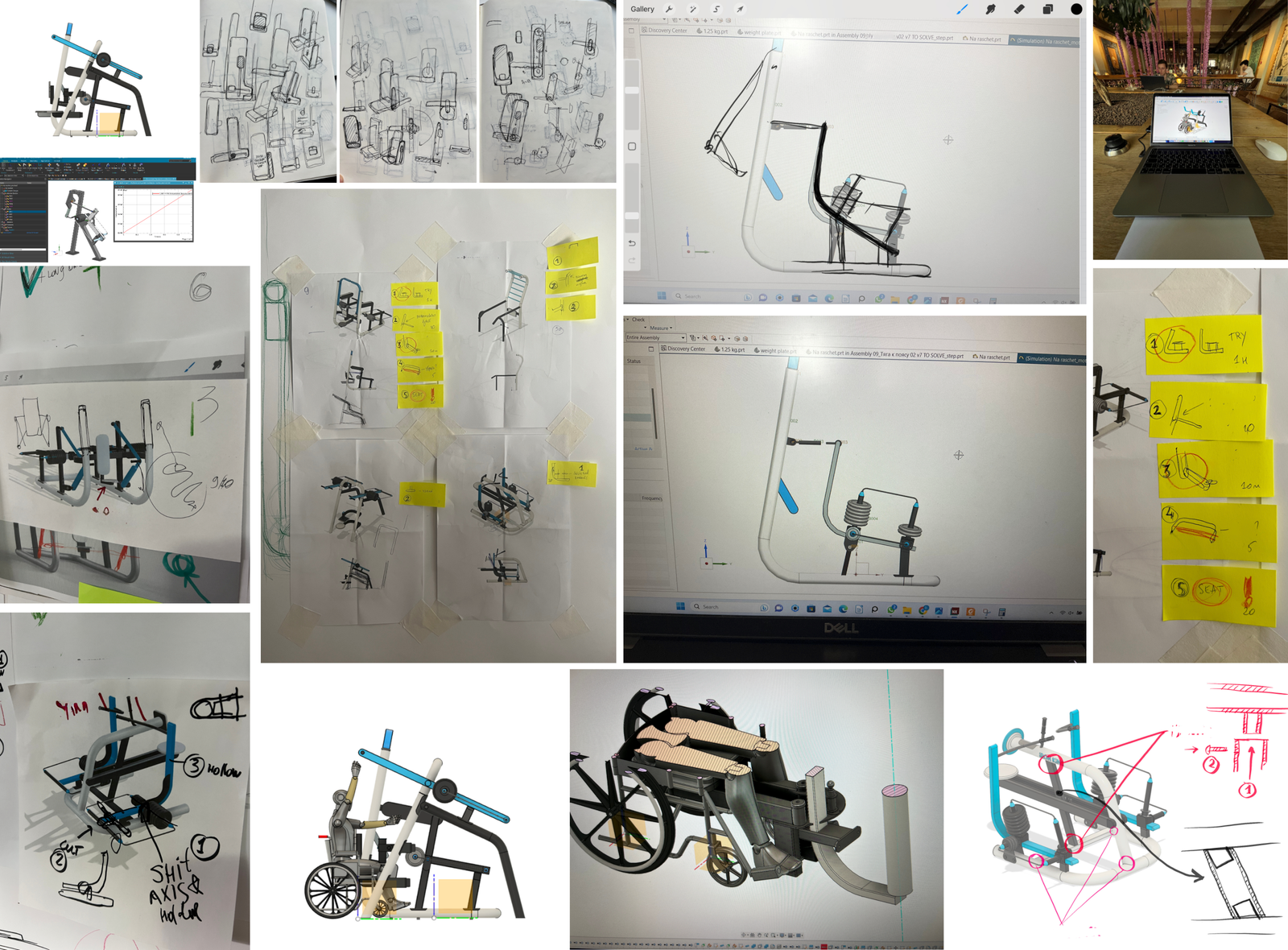

4. Concept Ideation & Industrial Design

Early concepts were generated around three pillars: safety, inclusivity, and production feasibility. Accessibility was treated as a foundation, while ergonomic refinements were scheduled for later prototyping stages to ensure real-world testing.

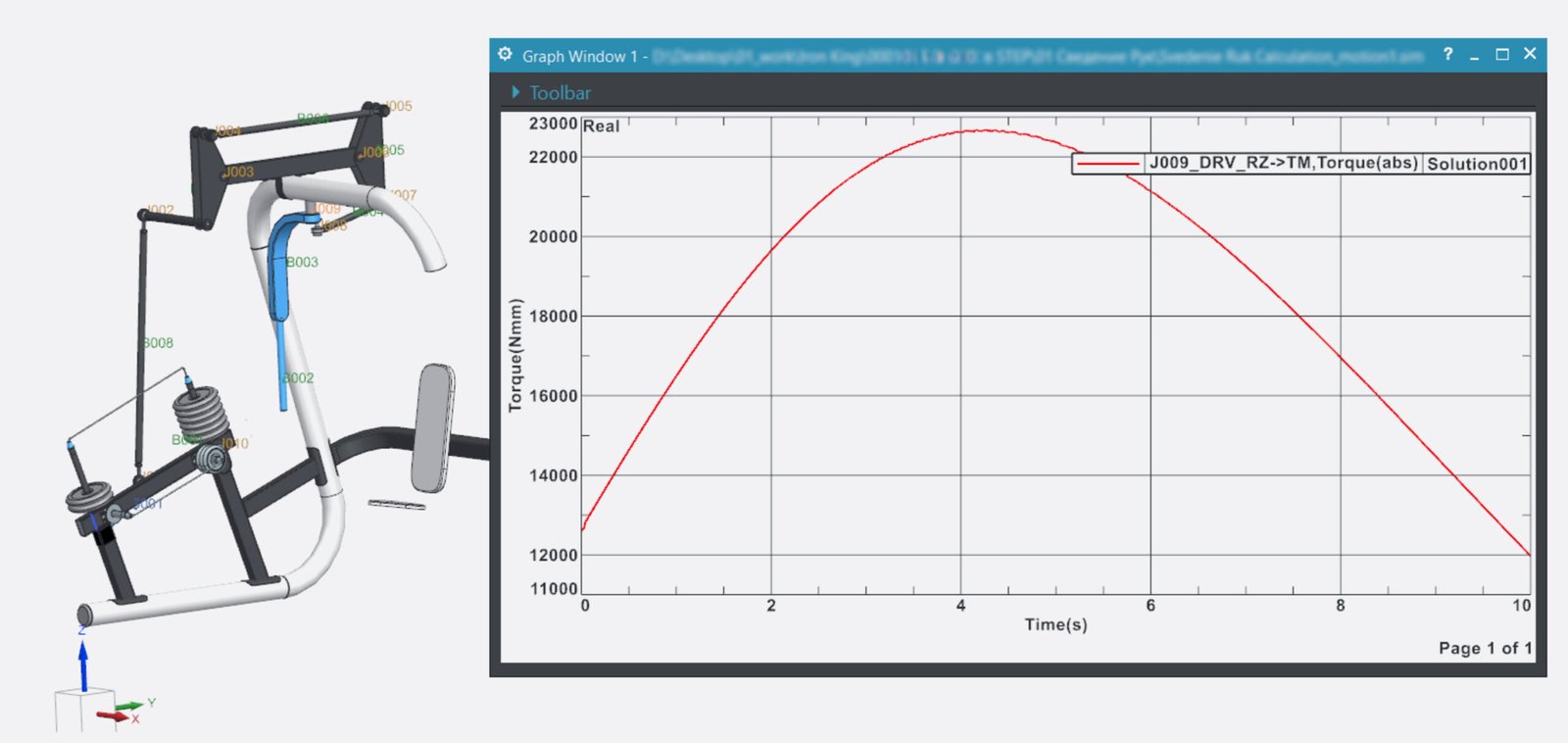

We re-engineered every lever—placement, pivots positions, length, and weight load—to align with the concept of Arranged Chaos. At each stage, simulation analysis ensured that functionality and aesthetics worked seamlessly together.

5. Prototyping as Strategy Testing

Prototypes became experiments to test core ideas: reducing welding to save time, cutting weight by 40% to lower delivery costs, and improving user ergonomics through iteration. Each round turned abstract strategy into tangible insights.

6. Production Strategy & Supervision

Once designs were finalized, production moved forward with close supervision. Every step — from welding to finishing — was monitored to align execution with design intent, ensuring both quality and efficiency.

7. Strategic Outcomes

- Reduced production time through optimized manufacturing processes.

- 30-40% lighter machines, cutting delivery expenses.

- Inclusive design, accessible for wheelchair users.

- Improved ergonomics and UX through iterative refinement.

- Distinctive identity, welcoming frames as a recognizable visual signature.

8. Conclusion: Design Thinking in Action

This project demonstrates how research, immersion, and prototyping converge into design strategy. The final machines are not only functional products but the outcome of a structured innovation process—translating insights into inclusive, efficient, demanded and impactful design.

Timeframe: 3 months from the request to CAD files of 10 inclusive gym machines, ready for Mechanical Designers work for preparing documentations for production.

Team: Mick and Mechanical Engineer for Simulation Analysis and CAD modeling support for 3 of 10 machines.

Mick’s role: client communication, design strategy, concept development, CAD modeling, renderings, pitching, leading cross-functional team, sourcing, prototyping supervision and support.